CUTTING TO SIZE AND TRADING

OF STAINLESS STEEL QUARTO PLATES

WATERJET CUTTING

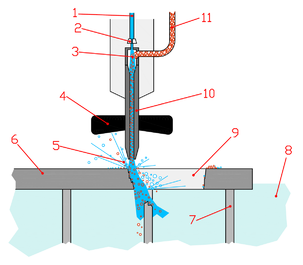

Waterjet technology uses a thin stream of water traveling at extremely fast speeds and under very high pressure (2000 - 6000 bar) to "erode" the material being cut. The process is essentially the same as water erosion found in nature but greatly accelerated and concentrated. The so-called "pure waterjet" machine tools use only water and are principally employed for cutting softer materials. In this application they are able to produce cut parts quite quickly. The "abrasive waterjet" machines add to the water an abrasive material (usually granite) that makes the cutter effective for shaping much harder materials like metals and ceramics. The speed of producing metal with waterjets, or other hard parts, is much slower but still competitive and highly accurate. Manufacturers often develop waterjets with the head submerged in a water table to reduce the noise produced by this process.

Advantages and Disadvantages of Waterjet Cutting

A major advantage of waterjet technology is its ability to cut virtually any material. Another advantage is that it doesn't superheat the area adjacent to the cut, so the material integrity is left intact. This is important in many types of metals which could be compromised or weakened due to additional heat. Waterjet is considered a "green" technology. Waterjets produce no hazardous waste, reducing waste disposal costs. They can cut off large pieces of reusable scrap material that might have been lost using traditional cutting methods. Parts can be closely nested to maximize material use, and the waterjet saves material by creating very little kerf. Waterjets use very little water, and the water that is used can be recycled using a closed-looped system. The granite abrasive is a non-toxic natural substance that can be recycled for repeated use. Waterjets also eliminate airborne dust particles, smoke, fumes, and contaminants from cutting materials such as asbestos and fiberglass. The accuracy of the process is acceptable for all but the most precise cuts, and the purchase price and maintenance costs of the machine are comparatively low.

On the other hand, waterjet technology cuts slower than plasma cutting process, reducing material processing productivity. Additionally, waterjet technology has a higher entry cost than the plasma cutting machines and the abrasive material used for cutting harder materials tends to be quite expensive.

Operation

The cutter is commonly connected to a high-pressure water pump where the water is then ejected from the nozzle, cutting through the material by spraying it with the jet of high-speed water. Additives in the form of suspended grit or other abrasives, such as granite and aluminum oxide, can assist in this process.

Waterjet (injection) cutting machine functional diagram

1: high-pressure water; 2: jewel (ruby or diamond; 3: mixing tube; 4: deflector; 5: splashing water; 6: cut material; 7: supporting grid; 8: water; 9: cutted surface; 10: nozzle; 11: abrasive

The kerf, or width, of the cut can be changed by changing parts in the nozzle, as well as the type and size of abrasive. Typical abrasive cuts are made with a kerf in the range of 1,016 to 1,270 mm, but can be as narrow as 0,508 mm. These small jets can make very small detail possible in a wide range of applications.

Process

There are six main process characteristics to waterjet cutting:

- Uses a high velocity stream of abrasive particles suspended in a stream of ultra high pressure water

- Is used for machining a large array of materials, including heat-sensitive, delicate or very hard materials.

- Produces no heat damage to workpiece surface or edges.

- Nozzles are typically made of sintered boride.

- Produces a taper of less than 1 degree on most cuts, which can be reduced or eliminated entirely by slowing down the cut process.

- Distance of nozzle from workpiece affects the size of the kerf and the removal rate of material.

Edge quality

Edge quality for waterjet cut parts used by Inox Service Hungary is defined with: BASIC, GOOD and FINE. Basic quality indicate rougher edge finish, the other two cutting qualities are smoother. Usually the cutting speed for quality „Basic” is three times faster than the cutting speed of quality „Fine”. As a result, the cutting price for quality „Fine” will be three times expensive than the cutting price for quality „Basic”.

|

|