CUTTING TO SIZE AND TRADING

OF STAINLESS STEEL QUARTO PLATES

WIDE RANGE OF HEAVY PLATES

FROM 10 mm TO 150 mm THICK

ELIMINATE YOUR SCRAP LOSS

ORDER CUT-TO-SIZE PLATE PRODUCTS

Questions and Answers

| 1./ How should the machining allowance be applied? What should the cutting dimensions be like? | → Answer |

| 2./ How do I choose which stainless steel to use? | → Answer |

| 3./ Which cutting method should we apply? Why that one? | → Answer |

| 4./ Is there a minimum order for quantity or amount? | → Answer |

| 5./ Can the invoice made out in Euros be paid in Hungarian Forints? | → Answer |

| 6./ Can a short delivery time be requested? | → Answer |

| 7./ Is it possible to order full plates as well? | → Answer |

| 8./ Do we deal with small companies and private individuals? | → Answer |

| 9./ Are we open to meet other requirements? | → Answer |

| 10./ Do we also cut thin sheets? | → Answer |

1./ The value of the machining allowance is one of the most frequent topics I come across during my work. In my experience not everyone knows about its practical application and a lot of people are not familiar with the relevant standard requirements.

The quality tolerances and the geometrical product specifications of the thermally-cut work pieces are specified and explained in International Standard EN ISO 9013.

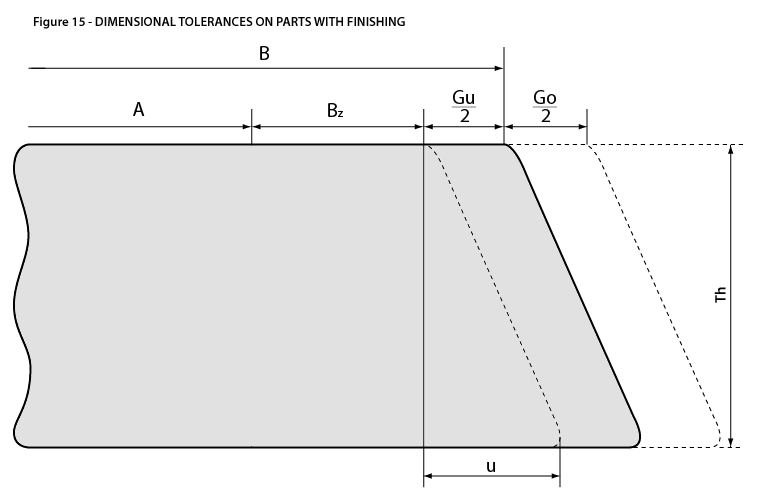

| A | nominal dimension of finished past |

| B | nominal dimension of cutting past |

| Bz | machining allowance |

| Gu | lower limit deviation |

| Go | upper limit deviation |

| u | perpendicularity tolerance |

| Th | work piece thickness |

In order to calculate the cutting dimension (B), we have to know the finite dimension (A):

B = A + 2Bz + Gu

The cutting dimension can be calculated by adding to the finite dimension the value of the machining allowance and the cutting tolerance. The real value of the cutting dimension will be between (B – Gu) and (B + Go).

The dimensions in the drawings shall be taken to be the nominal dimensions, the actual dimensions being determined on the clean surfaces of the cut. The limit deviations for the cut surface quality (perpendicularity tolerance) are treated separately from the limit deviations for the dimensional deviations of the work piece in order to emphasize the different influences on the work piece.

3./ The choice of the cutting procedure on the one hand depends on the buyer’s requirements and on the other hand depends on the technological opportunities available. Plasma cutting is recommended in all cases where the work piece is machined afterwards. This procedure enables the quick and cheap cutting of different shapes (rectangles, rings, discs and various other shapes). Using this technology however it is not possible to cut precise and complex contours. That requires water jet cutting. This procedure is effective and flexible, it is however more expensive. It is excellent for cutting work pieces with precise and complex contours made from thinner and thick plates. Extremely smooth edges with close tolerance limits result from this process. There is no heat input during the process so no changes in the material structure or warping, characteristic of plasma cutting. Then there is the mechanical sawing (band sawing) technology for getting rectangles of various thicknesses, without machining afterwards, or possibly individually sized flat bars. It is characterised by straight cut surfaces and angled cut edges. Since during the cutting there is no heat input the deforming effect of the material is negligible. Even several layers of material can be cut at the same time, thereby increasing productivity and optimizing material availability. The biggest disadvantage of the procedure is that cutting up is only enabled along a plane or a 2D line.

4./ There is no minimum quantity or amount , we don’t apply such restrictions! There is only a single size criterion due to the 100x100 mm grid of the worktable. This means that at least one measurement of the part to be cut must be greater than 100 mm.

5./ It is of course possible to pay in Hungarian Forints for invoices made out in Euro. Inox Service Hungary Kft. trades imported materials, the price of which in Forints is subject to the daily exchange rate. Basically our prices in quotations are given in Euros and our invoices are issued in Euros. Payment in Forints of an invoice issued in a foreign currency is possible by the prior written consent of our company. The exchange calculations are based exclusively on the MKB Bank noted trading sales exchange rate due on the transfer date! We emphasise that we use the MKB foreign currency trading sales exchange rate valid on the transfer date and not the MNB middle exchange rate used for calculating the VAT content on the invoice! This is misunderstood or mixed up by some people, and can result in significant differences in amounts.

6./ Every company can have an emergency situation where parts need to be acquired quickly. This can be due to tight manufacturing deadlines or replacement of rejects. In this situation our company will apply an accelerated procedure to manufacture the material at the nearest service centre and will deliver it to the door by the next available collection despatch or if urgently required by direct delivery service. This can be implemented in the case of one or two companies a week for the maximum order of 3-5 pieces. The accelerated procedure has an additional expense, depending on the quantity requested and dimensions of the work piece. The cost of direct transport is defined by the weight of the delivery and the distance to the delivery address from the service centre.

7./ Full plates can also be ordered providing the service centre has sufficient quantity for carrying out the base activity, i.e. for cutting purposes. For optimal material availability we basically stock 6000x2000 mm sheet plates. It is also possible for us to order the raw material for you direct from the manufacturing plant providing sufficient quantity is required. Our service centres have excellent relationships with known and recognised manufacturing plants throughout Europe, with whom we regularly place our orders for goods. Any commercial discounts acquired will naturally be passed on to our partners.

8./ We also provide for small companies and private individuals if they primarily wish to take advantage of the base materials and services we offer. Our company is not engaged with supplying parts for domestic household appliances. Furthermore we do not undertake cutting up small quantities of thin sheet. It is not within our main profile to cut these small parts from thin sheet.

9./ It is of course possible to contact us with base material requirements differing from our main profile, providing it falls within similar category as the base materials or services which we use. We can offer copper and bronze coils, bands (also cut to size) various coloured and patterned stainless steel plates for decorative purposes (steel colour), titanium products, stainless steel forged products and flat steel.

10./ Stocks of sheets which we consider thin or semi-thin (0.5 ÷ 8 mm) are kept exclusively in our Italian service centres and these appear on our product list as supplementary base materials. These are stored in rolls and the minimum order is 1000 kg (the width is fixed and we only cut them longitudinally).

2./ Most decisions about which steel to use are based on a combination of the following factors:

a. What is the corrosive environment?

Atmospheric, water, concentration of particular chemicals, chloride content, presence of acid.

b. What is the temperature of operation?

High temperatures usually accelerate corrosion rates and therefore indicate a higher grade. Low temperatures will require a tough austenitic steel.

c. What strength is required?

Higher strength can be obtained from the austenitic, duplex, martensitic and precipitation hardening steels. Other processes such as welding and forming often influence which of these is most suitable. For example, high strength austenitic steels produced by work hardening would not be suitable where welding was necessary as the process would soften the steel.

d. What welding will be carried out?

Austenitic steels are generally more weldable than the other types. Ferritic steels are weldable in thin sections. Duplex steels require more care than austenitic steels but are now regarded as fully weldable. Martensitic and precipitation hardening grades are less weldable.

e. What degree of forming is required to make the component?

Austenitic steels are the most formable of all the types being able to undergo a high degree of deep drawing or stretch forming. Generally, ferritic steels are not as formable but can still be capable of producing quite intricate shapes. Duplex, martensitic and precipitation hardening grades are not particularly formable.

f. What product form is required?

Not all grades are available in all product forms and sizes, for example sheet, bar, tube. In general, the austenitic steels are available in all product forms over a wide range of dimensions. Ferritics are more likely to be in sheet form than bar. For martensitic steels, the reverse is true.

g. What are the customer’s expectations of the performance of the material?

This is an important consideration often missed in the selection process. Particularly, what are the aesthetic requirements as compared to the structural requirements? Design life is sometimes specified but is very difficult to guarantee.

h. Magnetic

There may also be special requirements such as non-magnetic properties to take into account.

i. It must also be borne in mind that steel type alone is not the only factor in material selection. Surface finish is at least as important in many applications, particularly where there is a strong aesthetic component.

j. Availability

There may be a perfectly correct technical choice of material which cannot be implemented because it is not available in the time required.

k. Cost

Sometimes the correct technical option is not finally chosen on cost grounds alone. However, it is important to assess cost on the correct basis. Many stainless steel applications are shown to be advantageous on a life cycle cost basis rather than initial cost.

The final choice will almost certainly be in the hands of a specialist but their task can be helped by gathering as much information about the above factors. Missing information is sometimes the difference between a successful and unsuccessful application.