CUTTING TO SIZE AND TRADING

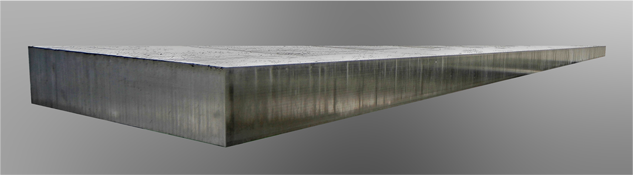

OF STAINLESS STEEL QUARTO PLATES

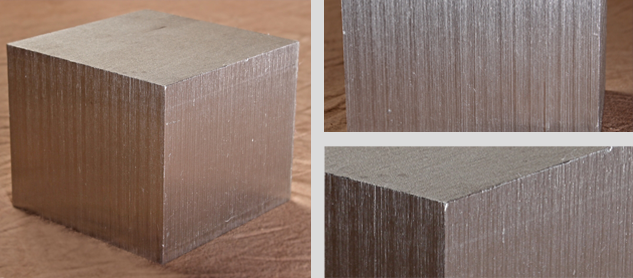

BANDSAW CUTTING

Bandsaw cutting is a cutting procedure carried out with a multi-edge cutting tool. It enables planar or two dimensional cutting along a line. The major movement is done by the tool which can have alternating, single direction infinite or rotating action. Machine sawing is done by using an infinite saw blade or slitting saw. The teeth on the tool depend on the quality of the material to be worked. For softer materials (e.g. aluminium or copper) tools having a bigger chip clearance and larger teeth are used, whereas for harder, more rigid materials (e.g. steel) tools with smaller teeth and a minimal chip clearance are used.

Advantages and disadvantages of bandsaw cutting

This technology guarantees a perfect vertical cut and fine finishing and minimizes the alterations of the mechanical characteristics of the material. A programmable controller ensures accurate and repeatable cutting head and plate feed movements. This means on-size and in-tolerance parts each and every time. A bandsaw cut edge does not have a heat-affected zone to machine through, saving you both time and tooling costs.

Ideal for rectangular plate and bars cut from plate from 10 mm thick to 150 mm thick. Additionally, the saws can cut narrow bars. This is especially useful for supplying bars cut from plate for non-standard bar sizes and types.

The main disadvantage of this technology is the limited shape possible to be cut. The bandsaw can cut only straight lines and tight curves. The other disadvantage is the long cutting, preparation and maintenance time.